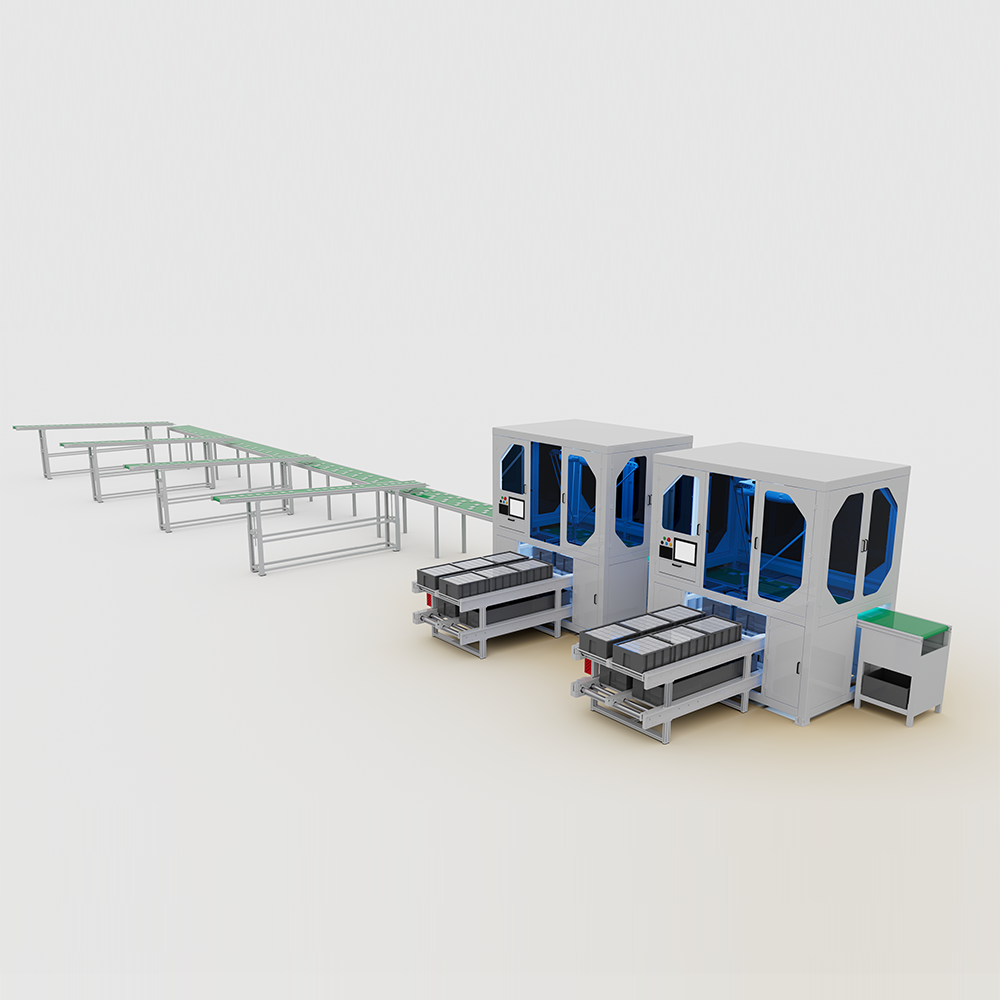

SCARA sorting equipment

The SCARA sorting equipment is designed to achieve fully automated boxing. The production line receives products from the injection molding machine, positions them via CCD for precise alignment, and identifies defective products. The SCARA robot then picks up the products and places them neatly into plastic boxes. This equipment allows seamless switching between any injection molding machine for automatic sorting.

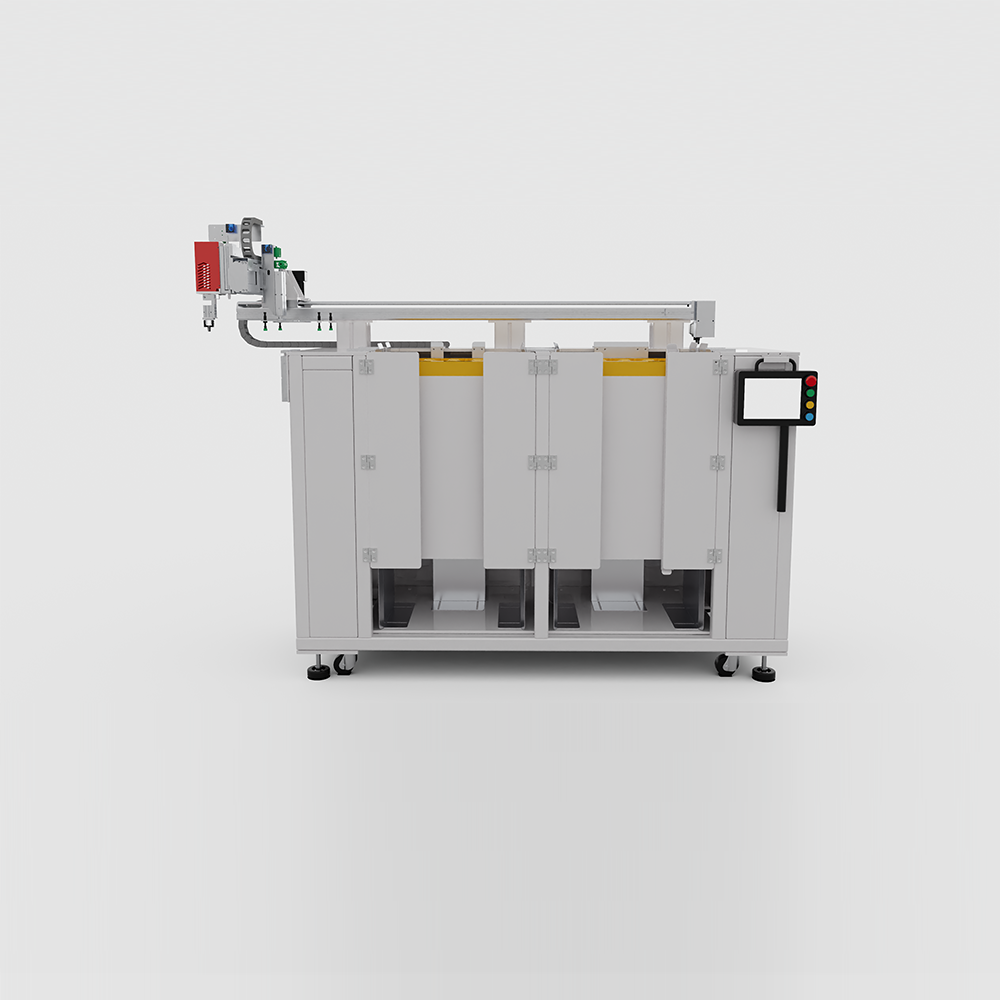

Plating Machine (Double-layer Belt Conveyor Line)

This equipment is primarily designed to enable automatic tray placement and stacking for products produced by the customer’s injection molding machines. It automatically loads a stack of empty vacuum-formed trays and uses modules to place products into the trays. Once a tray is fully loaded, it proceeds to stack the trays in sequence until all the trays are filled with products, followed by automatic unloading. This process reduces manual labor and improves production efficiency.

Single-Station Plating Machine

This equipment is primarily designed to enable automatic tray placement for products produced by the customer’s injection molding machines. It automatically loads an empty vacuum-formed tray, then uses modules to place products into the tray. Once the tray is fully loaded, the system performs automatic unloading. This reduces manual labor and enhances production efficiency.

Automatic tray placement and stacking

This equipment is primarily designed to enable automatic tray placement and stacking for products produced by the customer’s injection molding machines. Operators manually load a stack of empty vacuum-formed trays, and the module automatically places products into the trays. Once the stack of trays is fully loaded, operators manually perform unloading.

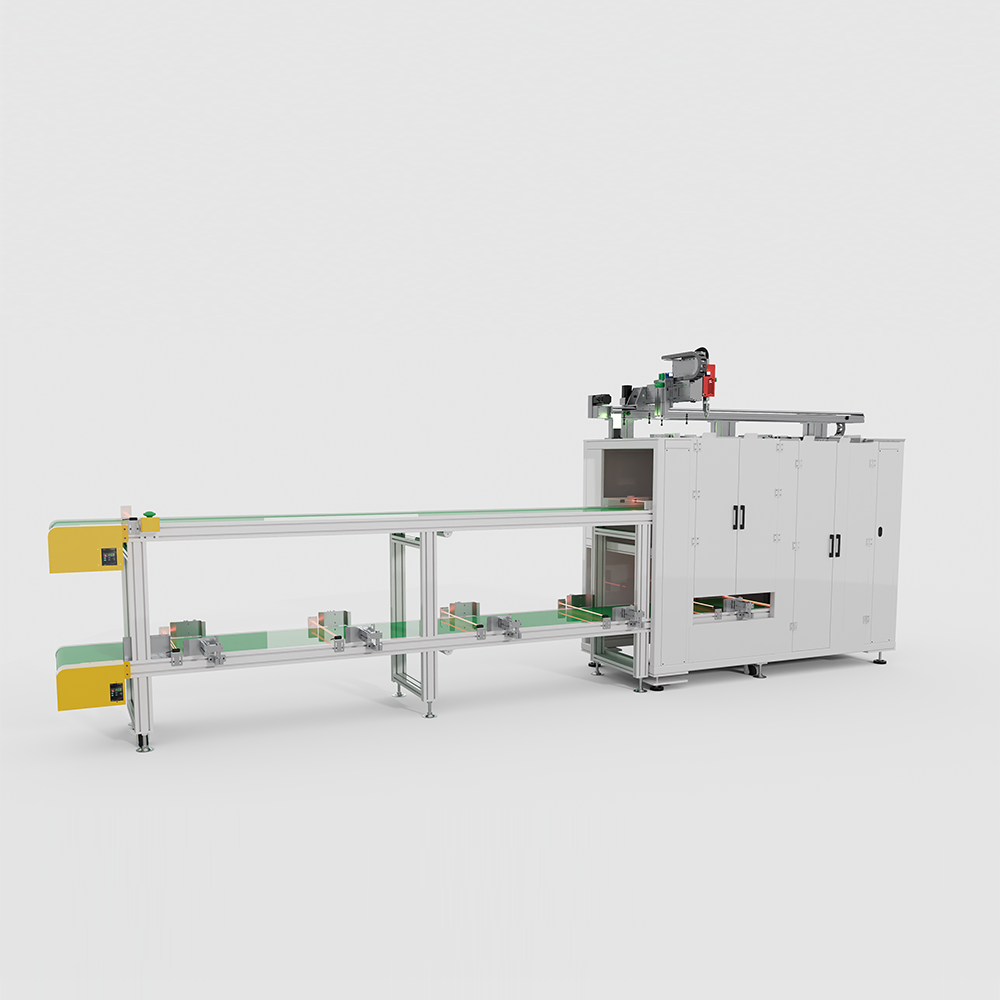

Fully automated product sorting and boxing

This equipment is designed for fully automated product sorting and boxing. Products from four injection molding machines are transferred via four conveyor sub-lines to a main conveyor line. The system uses CCD positioning to identify and sort defective products. Two parallel robots then pick up the products and load them into different plastic boxes. Only one operator is required to oversee the production from four injection molding machines, significantly reducing labor and improving production efficiency.

Double-layer Belt Conveyor Lifter

This equipment is primarily designed to enable automatic tray placement for products produced by the customer’s injection molding machines. It automatically loads an empty vacuum-formed tray, then uses a six-axis robot from the injection molding machine to place the products into the tray. Once the tray is fully loaded, the system performs automatic unloading. This reduces manual labor and enhances production efficiency.